Industrial Balancing

“We know how to treat valuable equipment; our technicians understand what it takes to make the parts we balance, and they have significant machining experience”.

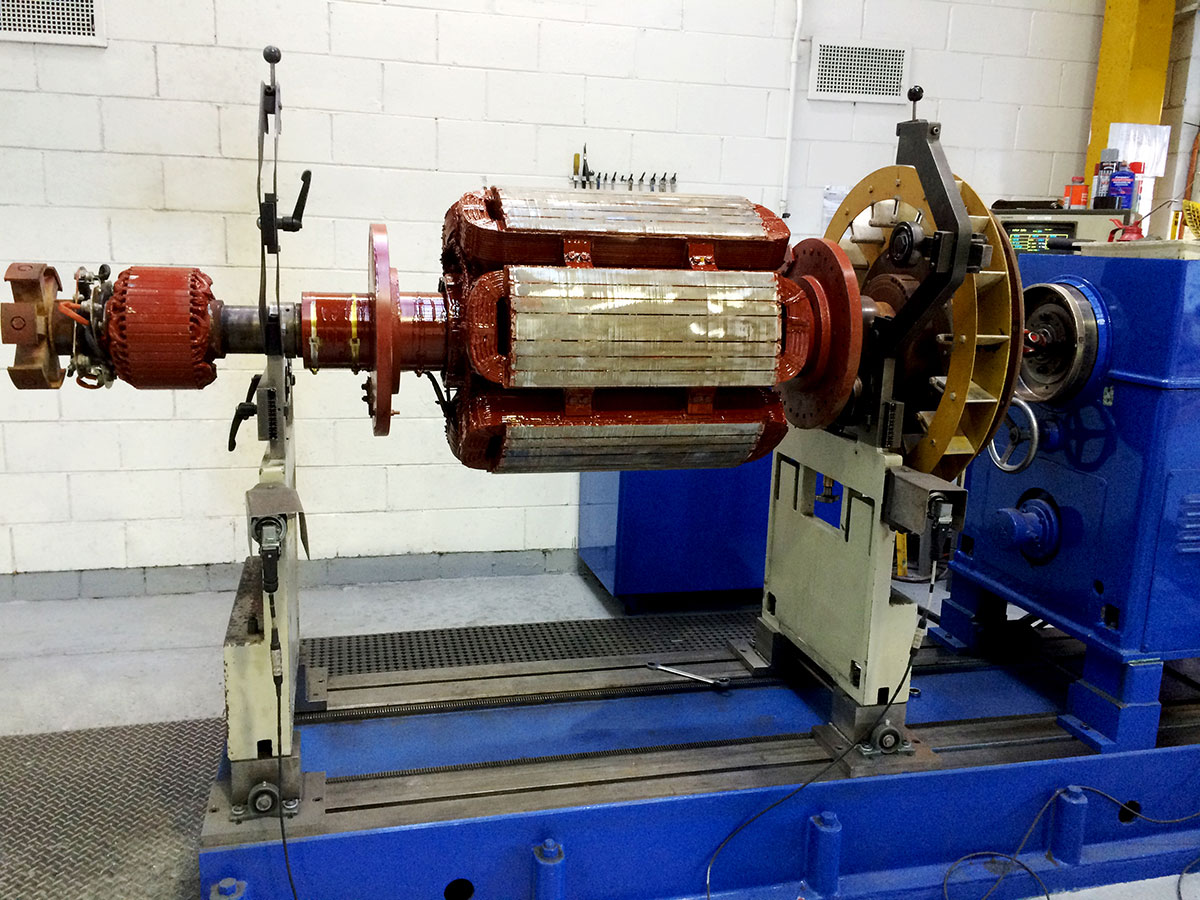

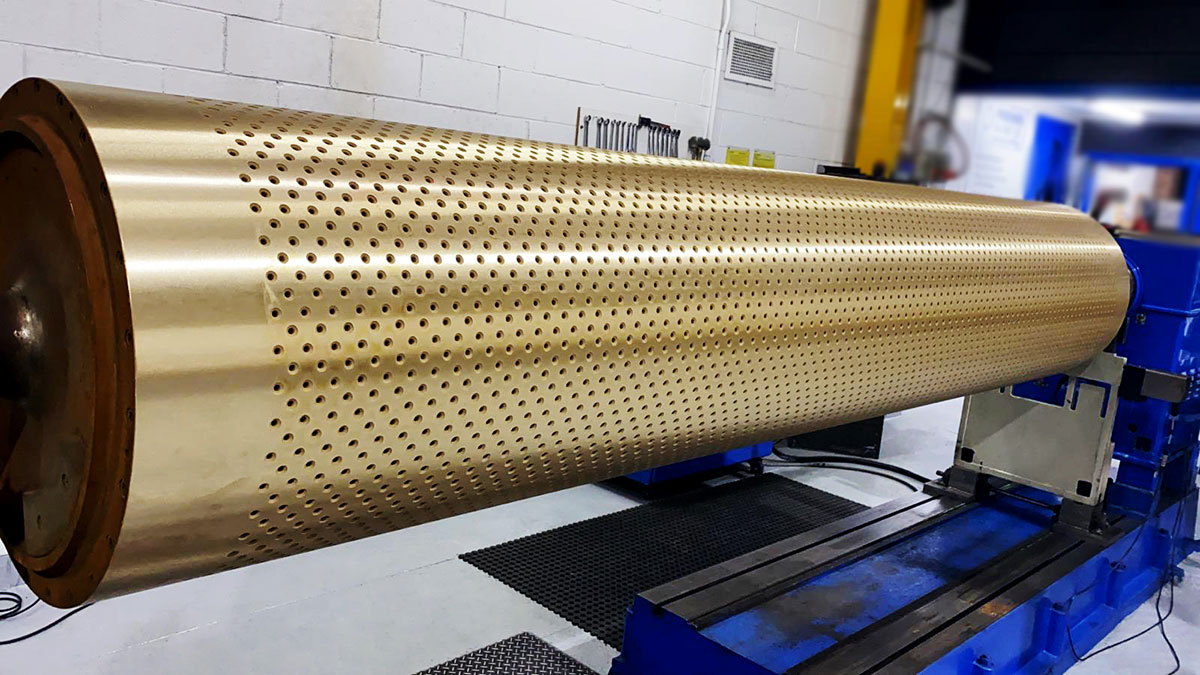

At Precision Balancing we offer a range of services including Dynamic and Static Industrial Balancing, Vibration Diagnostics, and Fault Investigation. We can perform static and dynamic industrial balancing, to the ISO1940-1-2003 standard, at the required quality grade (G1, G2.5, G6.3, etc)

We utilise a large variety of specialised equipment including a range of Schenck hard bearing balancing machines. We use digital technology and provide detailed printed reports for every project; we keep these reports on record for 5 years. The full report is given to the client including the values of the residual unbalance.

“We can balance the big nasty looking objects to the small delicate ones”.

The workshop features Schenk Hard-Bearing Balancing Machines including a H20, H30 and a H40. Precision Balancing also have a specialised balancing machine for tailshaft balancing.

The periodical servicing and calibration of our balancing machines is very important so we can continue providing optimal productivity, accuracy, and reliability. Schenck Australia regularly calibrates all the Precision Balancing machines and ensures all mechanical and electrical components operate and function to their optimum level.

To ensure our clients quality we follow a regulated procedure, to ensure your project is correctly handled:

- Every item that comes into the workshop is given a job number and job sheet, as a rule every purchase order must have a unique job number.

- Every Job sheet must show any balance speed and balancing grade required and any special requirements for the customer.

- Job is weighed and detailed on the job card.

- Job is allocated to the balancing machine appropriate to its size (i.e. H20, H30, H40).

- We calculate the balancing tolerance (based on weight and balancing grade required).

- We select an appropriately sized Mandrel (if the item does not have its own shaft.) and apply lubricant to the bearing surfaces.

- Input the item dimensions into the balancing machine and run the job. We add or remove weight to achieve dynamic balance within client’s specifications. Note that some jobs have specific requirements. e.g. Pump impellers are remove weight only. Special coatings may require bolt on Stainless Steel weights. Care must be taken to ensure added weights are of the same material and are welded using correct wire and gas.

- Print out Balance Certificate which has the job number and customers order noted on it. If the customer has requested supply a copy of the certificate with the job. (Print / Email)

Want to know more about Industrial Balancing and what we can do for you?

At Precision Balancing our experience is second to none giving us a unique ability to get the job done right…. First time! We can handle prototypes and even problematic components; we can take care of all of them.

Please contact us to discuss how our Industrial Balancing services can work for you.